|

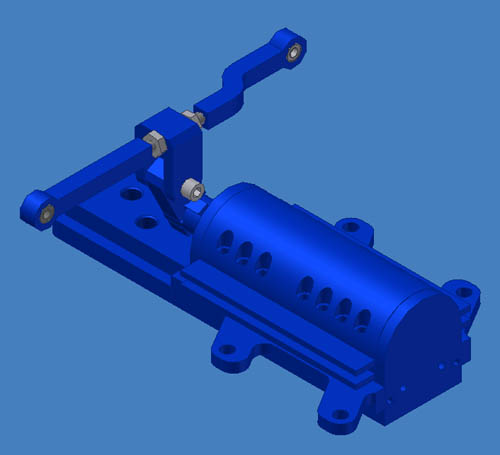

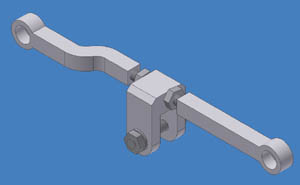

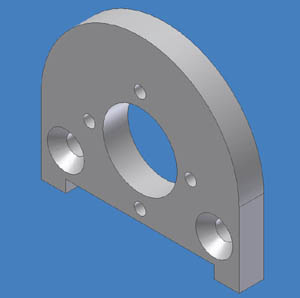

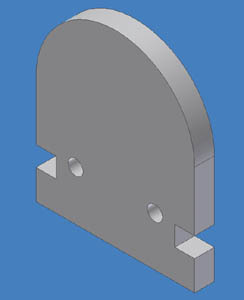

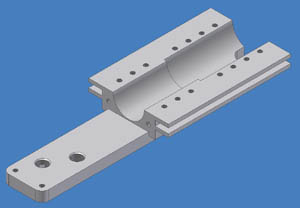

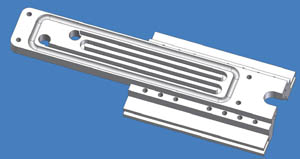

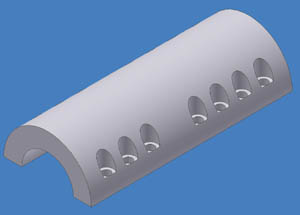

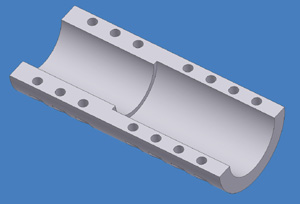

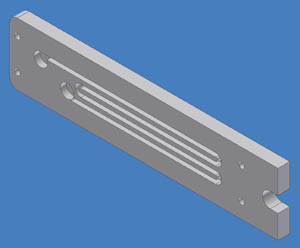

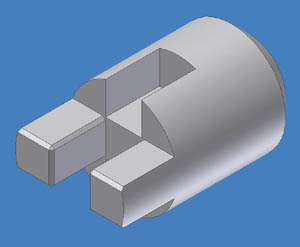

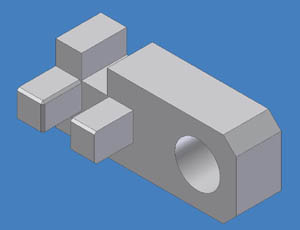

Motor Mount for Throttle Motor Scott did all the design for this motor mount and linkage using AutoDesk Inventor (and also created the images and text for this web page).

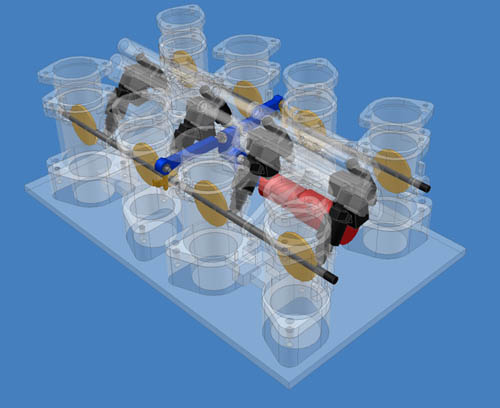

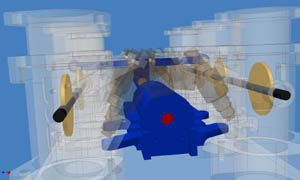

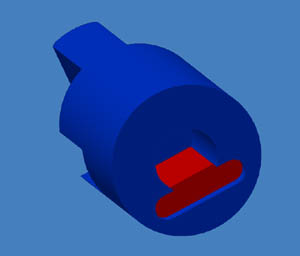

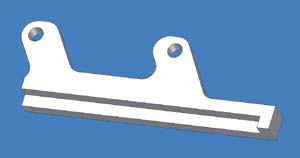

This is our induction system, a TWM Induction 50mm IDA V8 system. The throttle bodies are bolt on replacements for Weber 48IDA carbs. The motor, a MicroMo 3564 12V brushless motor with a 164:1 Series 30/1 gearbox, is shown in red. This will attach to a revised throttle linkage, shown in blue. |