|

Andy has a great website with lots of amusing stories about his build. He's made great progress on his car and is pretty close to completion now. We've learned a great deal from his mistakes and successes and I'm sure we'll save a lot of time as a result. Andy has also been extremely gracious in answering all our questions. Thanks Andy! |

||

|

I had last talked to Dave at JBL about three weeks ago to tell him we wanted to arrive on the 3rd. When I talked to him, he said they were still reasonably on schedule, but he wasn't sure if they'd be completely ready. I think he'd forgotten we were coming since he was a bit surprised when I called him from Andy's letting him know we were almost there. "Why don't you stop at Knott's Berry Farm for a couple days on your way here" |

|

| these were quickly solved. We finally called it quits for the day at

around 9:00 PM.

Richard, Dave, and one of the other JBL technicians agreed to work on the 4th to get us on our way - thanks guys! By 3:30 in the afternoon, we finally had the suspension assembled, the steering column in place with a borrowed steering wheel, and the wheels mounted. |

|

We rented an "Auto Transport" trailer from U-Haul to bring the car back home. The trailer worked out great - even with the super wide tires (335's in the back), the car fit |

||

| fine. We loaded up all the ancillary components - windshield, headers, side pipes, doors, trim panels, interior upholstery, door beams, etc. - inside the car with very little room to spare. The hood and trunk lids were taped in place with duct tape and a few other fiberglass parts (hood liner, trunk liner) were tucked into the interior. We were finally on our way at 4:30 in the afternoon. | ||

|

July 8 - We made it home at around noon on Friday (July 6). The only significant problem we had was with our car air-conditioning. For some reason, the climate control fuse was blowing after 10-15 minutes. After changing it a couple times, we gave up and lived with the heat. It was 110 degrees and 80% humidity in central CA, which was not fun, but once we got to Oregon the weather was very pleasant. We've spent a little time laying out the wiring harness and ordering parts to mount the |

||

|

July 15 - We've been so busy working on the car that we haven't had a chance to post to our journal. Our first week with our "kit" has been exciting, interesting, and just a bit frustrating. Looking back on the week, we accomplished quite a bit, but it seemed like every time we started to do something, we'd run into a problem where we had to run down to the local hardware store or order a part from the web. If we couldn't get the part |

|

|

| locally, we'd go on to

something else until we hit another road block. I think we placed at

least a dozen internet orders this week, and the UPS driver is getting

to know us really well. Fortunately, he seems genuinely interested in

our car project and has been happy to schlep all the boxes into our

garage so he can get another look at the progress.

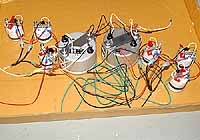

Our first challenge was to figure out where we were going to put everything that we needed to attach to the car. The list includes the fuse box, engine computer, MAP manifold, radar detector sensors, horns, stereo head unit, stereo amplifier, accusump (more on this in a bit), remote oil filter, oil "puke tank", fuel filters, and coolant overflow tank. We have more-or-less figured out most of these, but we need to wait until we get the radiator fan and the brackets for the anti-roll bar linear actuators before we can tell if everything will fit. We received our computer on Monday and discovered that it was just a little too big to fit on the chassis panel we had selected. Instead of moving it, I designed a custom bracket that we're having fabricated by our machinist. It's currently temporarily installed with two bolts until we get the new bracket. We also found that bracket that was supposed to be designed for a 351W to hold the crank trigger sensor did not fit our timing cover. So, another drawing to our machinist for a custom bracket. |

||

|

We had thought that the computer came with a fuel injector wiring harness, but this was not the case. We had to order individual fuel injector plugs and make our own harness. The plugs arrived on Thursday and Scott was able to get them all wired up and installed so our induction system is now fully assembled. |

|

The first major task to putting the car together is installing the wiring harness and routing the fuel lines (since the brake lines and fire suppression system had already been installed before we brought the chassis home from JBL). The wiring harness that came with the JBL is fairly complete, but we still needed additional wiring for the stereo, radar detector, extra gauges, accusump, and linear actuators. For anyone planning to |

|

|

| build a car - if you want to save time and frustration up

front, make sure you have a selection of fasteners and

wiring

accessories on hand before you start.

When we were at the Vintage races at SIR last weekend, we met a few people that had Accusump systems in their cars. This is a pressurized oil canister that connects to your oil system. It serves two purposes - it maintains oil pressure in case the oil sloshes away from the pickup in high-G turns, and it allows oil to be flowed through the engine before you start it. We're installing a 2 qt system which is the recommended size for our engine. This is a cost- effective and space efficient alternative to a dry-sump system for limited race use. The other time consuming task for this week was working on the fuel and oil lines. We are using Earl's Performa-flex hoses and Swivel-Seal fittings. There are a lot more hoses and fittings required than you might first imagine. The hoses take a bit of time to assemble, but they're not as hard or frustrating as I'd been led to believe. |

||

|

July 22 - It seems like it's taking forever, but we're finally making some serious progress on the wiring. We've finished all the wiring to the rear of the car, which includes the rear lights, battery, stereo, fuel sender, radar detector, and linear actuator for the rear anti-roll bars. We decided to mount the stereo head unit in the back of |

|

|

|

the car between the seats (we still have to make the mounting bracket). It will be accessible from the passenger compartment, but will normally be covered by an access panel. We're going to mount an IR repeater under the dash so that the stereo can be controlled with an IR remote control (whose home normally be in a door pocket). |

||

|

We also finished routing the fuel lines from the fuel cell to the front of the car. There are three lines - one from the fuel cell to the fuel rails, via two fuel filters and the fuel pump; a return line from the fuel pressure regulator back to the fuel cell; and a vent line so that the fuel cell can be vented into the engine air filter so that fumes are pulled back into the engine. |

|

The positive battery cable is routed through a battery cutoff switch. The negative battery cable is grounded to the chassis near the back of the car. To reduce the number of times we have to expose the bare chassis through the powder-coat, we've also run additional ground lines from the chassis grounding point to terminal blocks in the engine bay. These will be used for the ground wires required for devices in the front of the car. |

|

|

The steering column comes in bare steel, so it needs to be painted or it will rust. We put on a couple coats of primer and a few coats or Rustoleum flat black, but it needs a couple more coats before we can reinstall it. We also picked up the hub adapter for our Sparco wheel, so that can be mounted as soon as the column is back in. Tomorrow (Sunday), we hope to get the bracket made for the stereo head unit, and start working on the gauge wiring. July 31 - I'm falling behind on updating this site. We didn't spend as much time on the car this past week since we had other things to do, and spent the weekend visiting friends in the San Juan Islands. Many of the local Cobra owners got together for a BBQ and drive and it sounds like they had a great time. We're sorry we had to miss it, even though we don't yet have a Cobra to drive. We decided to get Jorge to make the brackets for the stereo head unit for us, so we sent him some drawings instead of trying to fabricate them ourselves. We dropped the headers and sidepipes off at a local welder to get small clips welded on to fasten the sidepipes to the headers. We decided to use the same approach that fellow-JBL- builder Andy is using - clips welded to each pipe with springs across the joint. We'll post a photo as soon as we can. We also had a fitting for the HEGO sensor welded into one of the collectors. The welding was done in a couple days, so we picked up the pipes and headers and drove them down to Performance Coatings in Auburn to have them ceramic coated |

| with CermaChrome.

This is a high temperature coating that looks similar to chrome plating,

but stands up to the heat much better.

We also tracked down the alignment dowels needed for the clutch and, thanks to Andy, found a source for a clutch alignment tool. So we're just about ready to install the clutch and transmission so that we can install the engine. |

|

|

Scott spent some time wiring up the gauges and doing a little more wiring in the front of the car. I finished painting the steering column and we got that re-installed with the new steering wheel. I've also expanded the links section - adding a few more links to sources for parts and tools. |

|

|

Next Month - Install the engine, start on the dash. |

||