Scott has been working a lot

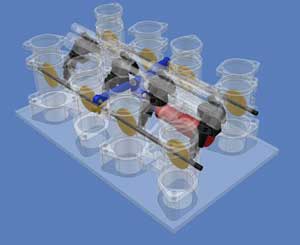

on the electrical system and has wired up and tested the anti-roll bar

linear actuators, the radiator fan, the head lights (including high/low

beam switching), the fuel pump controller, dash lights and gauges, horn

(it's LOUD), and accusump. He also wired up the radio, but it doesn't seem

to be working yet - still debugging.

I

designed a circuit for the

LED bar graph to indicate the position of the linear actuators and Scott

did the PC layout. We

found an online

company that does inexpensive PC fabrication and should have the PC

board by the end of the week.

Scott's been

working on mechanical drawings for our throttle control while I've been

working on the control electronics. I'll post more details in a couple of

days.

July 19 - Scott spent the day at

Portland International Raceway taking the

Advanced

Driver Safety course at Prodrive. He's also signed up for their

Introduction to Road Racing course later this summer.